While it has been established that solar panels are an excellent source of clean energy – they are efficient, versatile, and relatively cost-effective. Some might be concerned about the manufacturing process and its impact on the environment.

Here we explain how solar panels are made to demonstrate that, while there are some issues with the process, overall solar energy still comes out far and above the winner over non-renewable energy sources.

The Materials used in Construction

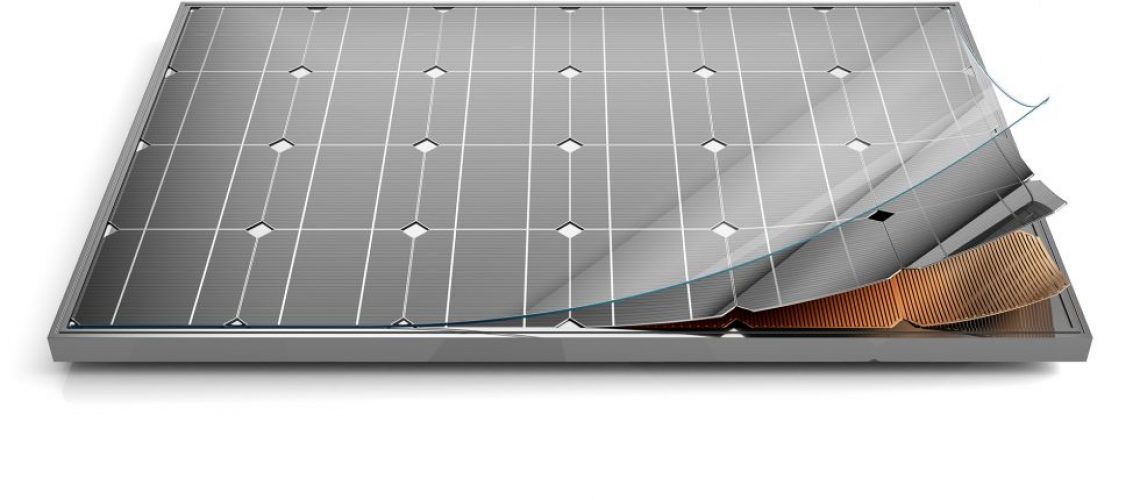

A solar PV module is comprised of solar cells, glass, a back sheet, and a frame. The solar cells themselves are created from silicon, a nonmetal with conductive properties that can be used to convert sunlight into electricity.

The Types of Panels Available

There are currently three types of solar panels available on the market: monocrystalline, polycrystalline, and amorphous or ‘thin-film.’ Each of these differs a little in terms of construction and efficiency.

- Monocrystalline solar panels, the most efficient kind, are produced from a single, large silicon block. The construction process involves cutting away wafers of the silicone from that block and affixing them to a solar panel. Creating these panels is more labor-intensive, and consequently, they are more expensive than others. These premium-range panels are easily recognizable by their black color.

- Polycrystalline solar panels, rather than being formed from a large block, are produced by melting multiple silicon fragments together to form the ‘wafers’ for the panel. While being less efficient than monocrystalline solar panels, polycrystalline panels are additionally less expensive. These panels often have a kind of bluish hue.

- Finally, amorphous solar panels, although very inefficient compared with both monocrystalline and polycrystalline types, are incredibly versatile due to their lean and bendy composition – quite unlike those other types of panels. In their construction, non-crystalline cells are deposited in thin layers to a substrate such as glass, plastic, or metal.

The Manufacturing Process

Aside from the specific differences associated with the construction of the silicon cells themselves, parts of the creation of the solar panels are similar for each type.

- Silicon is collected, usually in the form of solid rock. Hundreds of these rocks are melted together at very high temperatures to form cylinder-shaped ingots. Boron is added to the process, to give positive electrical polarity. After the ingot has cooled down, grinding and polishing leave it with flat sides.

- The ingot is then sliced into thin ‘wafers’ about the thickness of a piece of paper. The wafers are treated with an anti-reflective coating to ensure sunlight is captured rather than reflected away.

- The wafers are then applied to the frame of a solar module, and metal conductors are attached that give the panels the grid-like appearance. These create pathways for the electricity produced.

- Phosphorous is then diffused in a thin layer over the surface of the wafers, which negatively charges the surface. This combination of boron and phosphorous gives a positive-negative junction, which is critical for the proper function of the PV cell.

- The solar cells are soldered together, using metal connectors to link the cells.

- Once the cells are put together, a thin layer (about 6-7 mm) of glass is added on the front side, facing the sun. This provides protection against the elements.

- The back sheet forms the last layer of the solar panel. It is usually made from highly durable, polymer-based material to prevent water, soil, and other materials from entering the panel.

- A junction box is added. This houses and protects all of the electrical bits of the solar panel.

- Finally, the panel is placed within a frame, often of aluminum. This provides further protection to the cells and additionally allows for easy installation of the panels.